FM Cavity Filter

FM Cavity Filters are critical solutions for FM broadcast stations seeking interference-free transmission and optimal signal integrity. It works by allowing only the desired frequency to pass through and blocking other frequencies. This is important for FM radio broadcasting, as it helps prevent interference from other nearby radio stations, reduces noise, and maintains signal strength. In order to use a FM Cavity Filter in an FM broadcast station, it must be installed between the transmitter and the antenna. This will ensure that only the frequencies that the broadcaster wishes to transmit are sent out.

1. Precision Meets Power: Mastering FM Purity with Cavity Filters

At FMUSER, we specialize in RF broadcast engineering, delivering high-performance filters tailored for industrial-grade FM systems. This page categorizes our products based on frequency range, power capacity, and application scenarios, simplifying selection for professionals targeting urban broadcasting, emergency communication networks, or multi-station coordination.

2. Engineered Excellence: Key Features to Amplify Your FM Systems

FMUSER’s FM Cavity Filters are built for reliability and precision:

- Military-Grade Durability: Stainless steel construction with IP65 certification.

- Ultra-Low Insertion Loss: Maximize signal strength while blocking unwanted frequencies.

- Scalable Solutions: From 10W portable units to 10kW industrial systems.

- Certified Compliance: Meets FCC, CE, and global broadcast standards.

- Smart Tuning: Adjustable cavities for precise frequency control (±0.05MHz).

Designed for system integrators, broadcasters, and telecom operators, our filters adapt seamlessly to projects of any scale.

3. Beyond Broadcast: Diverse Applications of FMUSER’s Cavity Filters

Discover how our filters drive success across industries:

- 🗼 FM Radio Stations: Block adjacent-channel interference in crowded frequency bands, ensuring crystal-clear broadcasts. Pre-configured frequency bands reduce setup time by 50%.

- 🚨 Emergency Communication Systems: Prioritize critical signals during disasters with dual-band isolation. Ruggedized filters withstand extreme environments.

- ✈️ Aviation Navigation: Safeguard air traffic control frequencies from stray RF noise. FMUSER Benefit: Customizable attenuation slopes for strict aviation compliance.

- 📞 Private Mobile Radio (PMR): Secure fleet communications for logistics and public safety teams. FMUSER Benefit: Plug-and-play integration with existing transmitters.

4. Why FMUSER? Your Partner in RF Precision

- Factory-Direct Savings: Cut costs with wholesale pricing and 24/7 in-stock inventory.

- Turnkey Solutions: Pre-tuned filters, cabling kits, and on-site installation support.

- Rapid Global Shipping: 3-5 day delivery to USA/EU/Asia hubs.

- OEM Flexibility: Custom branding, frequency ranges, and port configurations.

- Proven Expertise: Trusted by BBC-affiliated broadcasters, NATO contractors, and Tier-1 telecoms.

5. Smart Selection Guide: Optimize Your FM Cavity Filter Choice

- Frequency Range: 88–108 MHz (standard) or custom bands (70–1000 MHz).

- Power Handling: 50W–10kW options for low-power repeaters or high-power transmitters.

- Compatibility: Verify connector types (N-Type, BNC) and impedance (50Ω).

- Budget Alignment: Balance upfront costs vs. long-term durability for ROI.

-

![FMUSER 87-108MHz 10000W FM Bandpass Filter 10kW FM Band Pass Filter With Custom Bandwidth for Transmitter System]()

Price(USD):Ask for a quotation

Sold:18

-

![FMUSER 87-108MHz 5000W FM Bandpass Filter 5kW FM Band Pass Filter With Coaxial Cavities for FM Radio Antenna System]()

Price(USD):Ask for a quotation

Sold:17

-

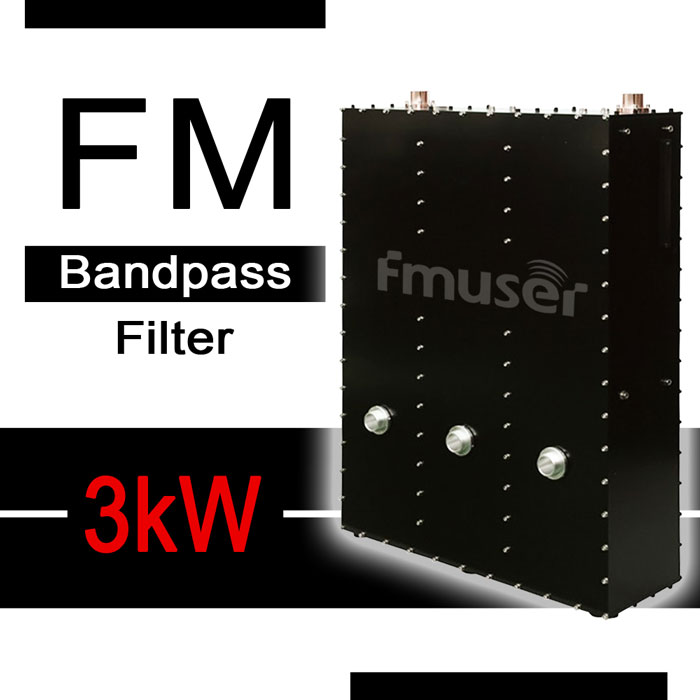

![FMUSER 87-108MHz 3000W FM Bandpass Filter 3kW FM Band Pass Filter With Tuneable Frequency for FM Radio Antenna System]()

Price(USD):Ask for a quotation

Sold:24

-

![FMUSER 87-108MHz 1500W FM Bandpass Filter 1.5kW FM Band Pass Filter With Tuneable Frequency for FM Radio Station]()

Price(USD):Ask for a quotation

Sold:35

-

![FMUSER 500W FM Bandpass Filter Low VSWR 87-108MHz Frequency Tuneable FM Band Pass Filter for TX RF System]()

Price(USD):Ask for a quotation

Sold:15

-

![20kW FM Low Pass Filter 87-108 MHz FM Broadcast Low Pass Filter for FM Transmitter and Broadcast Stations]()

Price(USD):Contact Us

Sold:51

- What is FM Cavity Filter?

- A FM Cavity Filter is an electronic device that is used to filter out unwanted signals from a frequency band. It is also known as a band-pass filter. It works by allowing only signals within a certain frequency range to pass through while rejecting all other frequencies. It is commonly used in radio communications systems to reduce interference.

- What are the applications of FM Cavity Filter?

- FM Cavity Filters are used in a wide range of applications, including radio and television broadcast, cellular, Wi-Fi and satellite communications, navigation and GPS systems, radar and military communications, and industrial applications. The most common applications include:

1. Radio and television broadcast: FM Cavity Filters are used to reduce interference between stations and optimize the reception of a particular station.

2. Cellular, Wi-Fi and satellite communications: FM Cavity Filters are used to reduce interference between wireless signals and prevent interference between wireless networks.

3. Navigation and GPS systems: FM Cavity Filters are used to reduce interference between GPS signals and optimize the accuracy of a particular system.

4. Radar and military communications: FM Cavity Filters are used to reduce interference between signals and optimize the performance of a particular system.

5. Industrial applications: FM Cavity Filters are used to reduce interference between signals and optimize the performance of a particular industrial system.

- How to correctly use FM Cavity Filter in broadcast station?

- 1. Calculate the amount of filtering needed before installation of the cavity filter. This should include the amount of power being used, the amount of attenuation required, and the acceptable amount of insertion loss.

2. Select the proper type of filter. This could include low-pass, high-pass, notch, or bandpass filters, depending on the application.

3. Mount the filter securely in the transmitter line, ensuring that the proper amount of isolation is maintained between the transmitter and antenna.

4. Make sure that the filter is properly tuned for the desired frequency. This includes using a spectrum analyzer to ensure that the filter is properly adjusted.

5. Monitor the output of the filter using a spectrum analyzer or field strength meter. This will help to identify any potential problems with the filter such as over- or under-attenuation.

6. Ensure that the filter is regularly inspected and maintained. This includes cleaning and replacing any worn components.

7. Avoid putting too much power through the filter or using it with a frequency outside of its intended range. This could result in excessive insertion loss or even damage to the filter.

- How does FM Cavity Filter work in broadcast station?

- An FM cavity filter is an important component of a broadcast station's radio frequency (RF) system. It is used to isolate the transmitter from the antenna feed line, preventing any unwanted signals from reaching the antenna. The filter is a tuned circuit consisting of two or more cavity resonators, each tuned to the desired channel frequency. The cavities are connected together in series, forming a single circuit. As a signal passes through the filter, the cavities resonate at the desired frequency and reject all other frequencies. The cavities also act as a low-pass filter, allowing only signals below the desired frequency to pass. This helps to reduce interference from other signals that may be present in the area.

- Why FM Cavity Filter is important and is it necessary for a broadcast station?

- FM cavity filters are essential components of any broadcast station, as they allow the station to control the bandwidth of the signal being transmitted. This helps to minimize interference and ensure that the signal being broadcast is as clear and consistent as possible. By controlling the bandwidth, the filter also helps to ensure that the broadcast signal meets the required power level and signal to noise ratio. This helps to enhance the quality of the broadcast signal and ensure that it reaches the intended audience.

- How many types of FM Cavity Filter are there? What is the difference?

- There are four main types of FM cavity filters: Notch, Bandpass, Bandstop, and Combline. Notch filters are used to suppress a single frequency, while Bandpass filters are used to pass a range of frequencies. Bandstop filters are used to reject a range of frequencies, and Combline filters are used for high-Q and low-loss applications.

- How to correctly connect a FM Cavity Filter in a broadcast station?

- 1. Start by disconnecting the antenna input from the transmitter, and connect it to the FM Cavity Filter.

2. Connect the FM Cavity Filter’s output to the transmitter’s antenna input.

3. Connect the power source to the FM Cavity Filter.

4. Set the filter’s frequency range to match the transmitter’s frequency.

5. Adjust the filter’s gain and bandwidth to match the transmitter’s requirements.

6. Test the setup to make sure it is properly functioning.

- Before placing a final order, how to choose the best FM Cavity Filter for a broadcast station?

- 1. Determine the frequency range and power requirements: Before choosing a filter, determine the frequency range and power requirements of the broadcast station. This will help narrow down the filter options.

2. Consider filter type: There are two main types of filters – low-pass and high-pass. Low-pass filters are used to reduce interference from signals that are higher than the desired frequency, while high-pass filters are used to reduce interference from signals that are lower than the desired frequency.

3. Check filter specifications: Once the filter type has been determined, check the filter specifications to make sure it will meet the power requirements of the broadcast station.

4. Compare prices: Compare the prices of various filter models to ensure you are getting the best value for your money.

5. Read customer reviews: Read customer reviews to get an idea of the filter’s performance and reliability.

6. Contact the manufacturer: If you have any questions about the filter, contact the manufacturer for more information.

- What are the equipment related to FM Cavity Filter in a broadcast station?

- 1. Cavity filter housing

2. Filter tuning motor

3. Cavity filters

4. Cavity filter controller

5. Filter tuning power supply

6. Isolation transformer

7. Filter tuning capacitor

8. Low pass filters

9. High pass filters

10. Band pass filters

11. Band stop filters

12. Antenna couplers

13. Sliding short-circuit components

14. RF switches

15. RF attenuators

16. Signal generator

17. Spectrum analyzer

18. Antenna system components

19. Amplifiers

- What are the most important technical specifications of FM Cavity Filter?

- The most important physical and RF specifications of FM cavity filters include:

Physical:

-Filter type (Bandpass, Notch, etc.)

-Cavity size

-Connector type

-Mounting type

RF:

-Frequency range

-Insertion loss

-Return loss

-VSWR

-Rejection

-Group delay

-Power handling

-Temperature range

- How to correctly perform daily maintainence of a FM Cavity Filter?

- 1. Check all connections for proper tightness.

2. Check for any visible signs of damage or corrosion.

3. Test the filter for proper insertion loss and bandwidth.

4. Measure the input and output levels of the filter to ensure correct levels.

5. Test the filter for proper response to any other equipment connected to it.

6. Test the filter for proper isolation between the input and output.

7. Check for any signs of arcing or sparking.

8. Clean and lubricate any mechanical parts of the filter.

9. Check the filter for any signs of mechanical or electrical wear.

10. Replace any parts of the filter that show signs of wear or damage.

- How to repair a FM Cavity Filter?

- 1. First, you need to determine what is causing the filter to fail. Check for external damage or corrosion, as well as any loose or broken connections.

2. Disconnect the power to the filter and remove the cover.

3. Inspect the components of the filter and check for any broken or damaged parts.

4. If any parts appear to be damaged or broken, replace them with new ones. Make sure to use the same type of parts for replacement.

5. Reassemble the filter, making sure all connections are secure.

6. Connect the power to the filter and test the filter to make sure it is working properly.

7. If the filter is still not functioning properly, it may need to be sent in for professional repair.

- How to correctly package a FM Cavity Filter?

- 1. Choose a packaging that will provide adequate protection for the filter during transportation. You should look for packaging that is designed for the specific size and weight of the filter. Make sure the packaging is strong and durable enough to protect the filter from physical damage and moisture.

2. Choose a packaging that is suitable for the type of transportation. Different modes of transportation may require different types of packaging. Consider the packaging requirements for air, ground, and sea shipments.

3. Ensure that the packaging is designed for the filter's specific environmental conditions. Different filters may need special packaging to protect them from extreme temperatures and humidity levels.

4. Label the package properly. Make sure to clearly identify the contents of the package, the destination, and the sender.

5. Secure the package properly. Use tape, straps, or other materials to ensure that the package won't be damaged during transit.

6. Check the package before sending it. Make sure that the filter is properly secured in the packaging and that the package is not damaged.

- What is the material of a FM cavity filter?

- The casing of an FM Cavity Filter is generally made of aluminum or copper. These materials will not affect the performance of the filter, but they may affect the size and weight of the filter. Aluminum is lighter than copper, so it may be preferable if the filter needs to be installed in a tight space or in a mobile application. Copper is more durable, so it may be preferable if the filter needs to be used in a harsher environment.

- What is the basic structure of FM Cavity Filter?

- FM Cavity Filter consists of several parts, each performing a specific function.

1. Resonator Cavities: These are the main structure of the filter and provide the actual filtering action. Each cavity is made up of a tuned, electrically conductive metal chamber that is tuned to resonate at a specific frequency. The resonator cavities are what determine the filter’s attributes and performance.

2. Tuning Elements: These are components that can be adjusted to fine-tune the frequency response of the filter. They are typically capacitors and inductors that are connected to the resonator cavities.

3. Coupling Elements: These are components that link the resonator cavities together so that the filter can provide the desired filtering action. They are typically inductors or capacitors that are connected to the resonator cavities.

4. Input and Output Connectors: These are the connectors where the signal is input and output from the filter.

No, the filter cannot work without any of these structures. Each component is essential for the filter to perform its filtering action.

- Who should be assigned to manage FM Cavity Filter?

- The person assigned to manage an FM Cavity Filter should possess technical expertise and knowledge about the operation and maintenance of the filter. This person should also have experience in tuning and troubleshooting the filter, as well as knowledge of electrical engineering principles. Additionally, the person should have good organizational skills and be able to keep detailed records of the filter’s performance.

- How are you?

- I am fine

CONTACT US

FMUSER INTERNATIONAL GROUP LIMITED.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us